“Teamwork makes the dream work.” It’s something you see written on t-shirts from the company retreat or on those motivational posters in the office of Judy from HR.

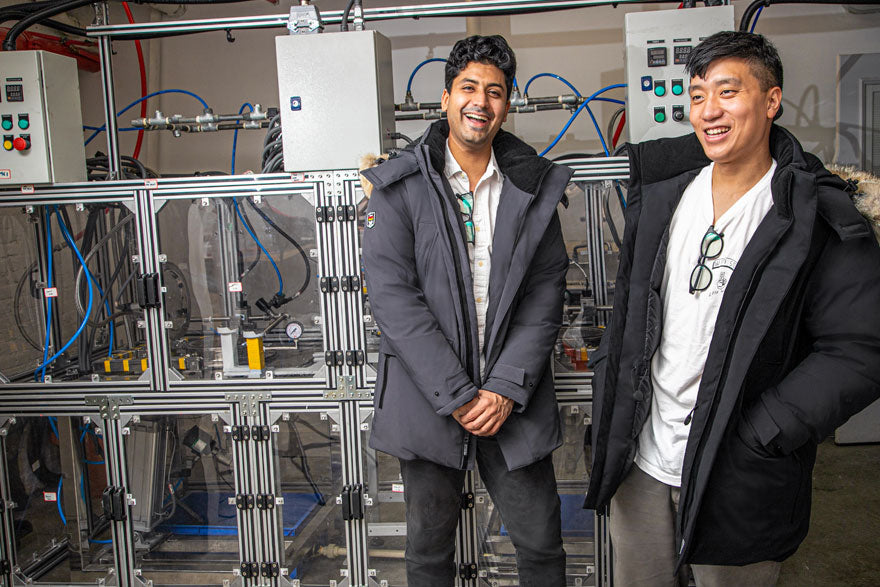

But the thing is it’s true, at least in the case of Sahir Zaveri and Dave Lee. The duo behind King Children, a custom 3D printed eyewear company, has combined their expertise to create a business model that’s a true game-changer.

Using 3D scanning and printing technology, they design and manufacture custom frames that perfectly fit customers’ faces. Oh yeah, and in doing it they create zero waste. None. Zip. Zilch.

Turns out people like nothingness—to the tune of $2 million in fact. Back in 2018, when they launched, that’s the funding they received from investors including Great Oaks Venture Capital, RBC Venture Partners, Gen Z Capital, and Casper mattress co-founder, Neil Parikh.

With big-time backing like that, it’s no wonder the Brooklyn based outfit was named one of the “50 Startups to Watch in 2019” by Built In NYC, the five borough’s startup and tech hub. Here we explore how embracing diversity helped Zaveri and Lee form their partnership, create their business and stay friends long after meeting in college.

STRENGTH IN NUMBERS

Usually, it’s our differences that keep us apart. But in the case of Zaveri, who’s from Mumbai, India, and Lee, a California native, it’s what has brought them together. They met as undergrads at Brown University when they were both living in the Buxton International House, which houses internationally minded students committed to fostering cultural exchange.

Despite their differing backgrounds, and though Zaveri was studying applied math and Lee was concentrating on economics and computer science, the two formed an instant bond.

“Living together in the Buxton International House was an important part of our college experience. It exposed us to the value of creating a business that caters to diverse people and that is built with an international identity rather than viewing itself as belonging to any single nation,” they say. “This is exemplified by our desire to build talent and a customer base in different parts of the world from our infancy as a company.”

Up until that point, all things pointed to Zaveri being a part of something like King Children. He grew up visiting factories and was appalled by the waste created by the process of creating consumer goods. He had an early interest in computer-aided design (CAD) and 3D printing to the point he became the youngest certified user of the Pro-Engineer Master Module in the world by PTC USA.

Lee brought a much more diverse background with him to Brown, having been active in wrestling, football, cross country, golf, and jazz band at the Milton Academy, a prestigious school in Massachusetts that counts Robert and Ted Kennedy among its alumni.

But instead of causing conflict, these distinct aspects of their personalities have brought the two closer together. More than that, they’ve allowed them each to take their own strengths to another level because they can rely on the other to pick up the slack in areas outside their immediate focus.

“I think our greatest strength as a team is how different we are as people. Sahir is naturally business savvy, comes from private equity, and has a great broad perspective on what’s going on in the company,” Lee explains. “I am more interested in the software, don't like to deviate from product development and have a propensity for tunnel vision.

“Sahir is naturally extroverted and extremely outgoing while I have some geriatric tendencies,” he adds. “I think a lot of responsibilities naturally fall into either one of our wheelhouses; however, we make sure to meet multiple times a week to ensure we stay aligned.”

One thing they can definitely agree on is that their dual mindset has a singular focus: King Children.

ONE COMPANY FOR ALL

Given their differences it shouldn’t come as a surprise that their company celebrates diversity. To fit faces of all sexes, ethnicities and body types, King Children allows customers to pick the color, shape and frame size of their glasses.

How individualized are the specs? Each one is made to order using a smartphone app or their website which measures your face. From there, 3D printing technology shapes engineering-grade plastic into frames, which are then sent out to customers within two weeks of their purchase.

Lee, who is Asian and growing up had trouble finding glasses that fit him, finds deep meaning in King Children’s ability to help large sections of the population long ignored by the eyewear industry.

“For me, creating a product that is personalized to each individual is extremely exciting,” he notes. “Realizing that most products in the market are designed for some standard, Hellenistic model of a person, I am proud to be part of a team that is designing glasses for each and every face.”

But the customized aspect of their glasses may not be their most impressive attribute. That’s because King Children’s manufacturing processes produce zero waste. More so, the impressive part of this isn’t the fact that they are putting less garbage in landfills, though that’s a biggie. It’s that they put their time and money to where their ideals are—something few companies have the guts or moral compass to do.

“It’s complicated and difficult to actually bring about a radical change in how we produce things, so companies pay lip-service to ideas like making eco-friendly products as that’s effective marketing, but aren’t actually driving any meaningful change,” they say. “We believe that made-to order using zero-waste production technologies is just a better way of doing things—for both the planet and our consumers, and have built on top of that.”

Their visionary spirit does end with how they manufacture their products—it also has to do with how they run their business. Case in point, they want to help the Brooklyn community they call home by supporting local creatives (artists, musicians, dancers, painters and more) who share the company’s values of inclusivity and self-expression. They’re doing this through their King Children Residency program.

“It was born out of our desire to help contribute to the communities that we’ve enjoyed so much to be a part of,” Lee says. “We wanted a means to help artists that we’ve run into during our stay in New York fund their projects and make their most insane dreams come to fruition.”

Zaveri and Lee’s dreams include expanding King Children to manufacturing other consumer products with zero waste using an array of high-tech production methods. “We have already developed a number of flexible production capabilities that are patented which we use in conjunction with 3D printing to create our eyewear,” they say.

But there’s a reason they chose to make eyewear first. Partly, it’s because making glasses the old way creates tons of waste—for a pair of acetate frames 80% of the material used goes to the landfill—but also because someone’s face is the first thing you notice about them.

“Eyewear is unique in that it occupies the most prime real estate on your body,” Zaveri explains. “It’s hard for people not to notice your eyewear so it says quite a lot about you. Increasingly, people are wearing a product like ours to show what they stand for—a ‘Zero Waste Future’ in our case.” And it says a lot about the company’s leadership as well.

FOOD FOR FRIENDSHIP

Technological advancements. Cultural inclusivity. Ecological dedication. Wish fulfillment. As you can probably tell, when you have so many ideas bouncing around your heads as Zaveri and Lee do, it’s not easy to decompress or even something you want to completely give yourself over to when your work is such an intrinsic part of who you are.

“You need to build enough time into your schedule to unplug so that you don’t lose track of yourself and what you are doing,” Zaveri notes. “Having said that, really unplugging takes time and it’s hard to force yourself to take a long enough break until you realize that you are starting to lose your mind!”

Case in point is Lee, who watches a lot of the NBA on TNT, but usually with one eye on the TV and the other on his laptop. “Watching basketball helps me unwind, and it helps that Charles Barkley is hilarious,” he says. “But typically I am still coding/doing work for the first three-quarters of the game.” For Zaveri, watching Netflix or putting on some tunes helps him “slow down” his mind.

Exercise is another way both try to take a break from the office life—with Zaveri preferring the gym and Lee going for rock climbing. They also differ on the shorter breaks they can work into their 9 to 5s.

Lee goes to Starbucks for the peppermint mochas they have only during the holidays. Walking down the Williamsburg waterfront is Zaveri’s choice for a winter break. “It is way less crowded than the rest of the year,” he says. “When you are wearing your Triple F.A.T. Goose you don’t need to worry about the wind or the cold!”

But just as in business, outside there is an intersection of their divergent interests that keep the two connected. For instance, Zaveri really loves to get creative in the kitchen. “I find it really de-stressing to spend hours on a weekend cooking a complex multi-course meal for friends,” he says.

For his part, Lee is very supportive of his friend’s passion. “We definitely still find time to hang out,” Lee says. “Sahir really likes to cook and I really enjoy eating free meals.” Sounds like a perfect fit.